Under Pressurized Diesel Exhaust Fluid System

SPN 4374/FMI 0

Description This Code Sets When the Diesel Exhaust Fluid (DEF) Pump Speed is Higher than Normal For a Given DEF Pressure

Monitored Parameter DEF Pump Speed, DEF Pressure

Monitor Sequence None

Execution Frequency Continuous When Enabling Conditions Met

Typical Duration Continuous Until Resolved

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification SCR ADS Self-Check

Possible causes:

• Restriction in the DEF line between the DEF tank and the DEF pump

•Restriction in the DEF line between the DEF pump and the DEF dosing unit

• Air in the DEF line between the DEF tank and the DEF pump

• Restriction in the DEF pump

•Failed DEF pump

Check as follows:

Show/Hide Checkboxes

NOTICE:

Customers in colder climates where winter ambient air temperatures generally stay below -11° C (12°F) need to verify that the DEF is not frozen before troubleshooting this fault code.

1. Connect DiagnosticLink® .

2. Turn the ignition ON (key ON, engine OFF).

3. Check for multiple codes. Are codes SPN 4334/FMI 3, 4, SPN 4375/FMI 3, 4, or SPN 3361/FMI 3, 4, 5 also present?1. Yes; diagnose and repair the other fault codes first. Verify repair.

2. No; Go to step 4.

4. Turn the ignition OFF.

5. Inspect the DEF tank vent tube. Is there any blockage or restriction?1. Yes; clear the restricted vent tube. Go to step 6.

2. No; Go to step 6.

6. Using DEF test strip A0005850202, check for diesel fuel or oil contamination of the DEF fluid. Does the test strip indicate contamination?1. Yes; replace the following components and refill the system with new DEF:

◾ DEF tank

◾ DEF tank header

◾ DEF supply line from the DEF tank to the DEF pump

◾ DEF line from the DEF pump to the DEF dosing unit

◾ DEF return line from the DEF dosing unit to the DEF tank

◾ DEF pump

◾DEF dosing unit

2. No; Go to step 7.

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

7. Inspect the DEF line that runs from the DEF pump to the DEF dosing unit. Is the DEF line damaged, pinched, or kinked?1. Yes; replace the DEF line from the DEF pump to the DEF dosing unit.

2. No; Go to step 8.

8. Inspect the DEF line that runs from the DEF tank to the DEF pump. Is the DEF line damaged, pinched, or kinked?1. Yes; replace the DEF line from the DEF tank to the DEF pump.

2. No; Go to step 9.

9. Disconnect the DEF supply line at the dosing unit. Fill the graduated cylinder supplied in DEF test kit (P/N: W060589001900) with water. Place the end of the DEF line into the graduated cylinder as far as possible.

NOTE: Place the graduated cylinder in a secondary container to catch over flowing DEF fluid, making sure you still have clear sight of the end of the DEF line.

10. Using DiagnosticLink, perform the Selective Catalyst Reduction Airless Dosing System (SCR ADS) Self-Check routine. When the service routine is running, visually inspect the DEF line for continuous air bubbles coming from the line and DEF flow.

11. Were any bubbles coming from the DEF pump supply line indicating a crack in the DEF pump feed line?1. Yes; replace the DEF supply line from the DEF tank to the DEF pump. Verify repair.

2. No; Go to step 12.

12. Remove the DEF tank header.

13. Inspect inside the DEF tank for debris that may be floating around or stuck to the DEF tank header pick up screen. Was any debris found?1. Yes; flush out the DEF tank and clean the DEF tank header filter screen. Go to step 14.

2. No; Go to step 14.

NOTICE:

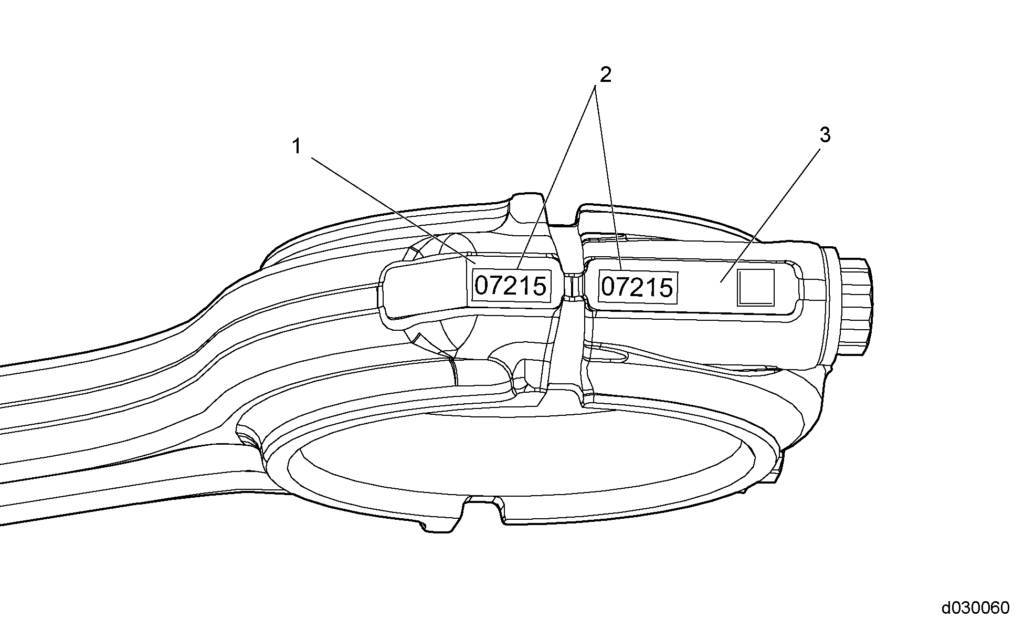

The RS SUPPLY KIT contains all the necessary parts for steps 14-17.14. Using the DEF/Doser Kit (RS SUPPLY KIT – available through eParts catalog), replace the DEF pump module filter. Refer to section “Installation of the GHG14 Diesel Exhaust Fluid Pump Filter” . Go to step 15.

15. Replace the DEF pump inlet screen. Refer to section “Installation of the Diesel Exhaust Fluid Pump Module Filter Screen” . Go to step 16.

16. Replace DEF Pressure Relief Valve (PRV). Refer to section “Removal of the Diesel Exhaust Fluid Pump Pressure Relief Valve” . Go to step 17.

17. Replace DEF dosing unit inlet screen. Refer to section “Removal of the GHG14 Diesel Exhaust Fluid Dosing Unit Inlet Screen” . Go to step 18.

NOTE: If air pressure is greater than 827 kPa (120 psi), use a pressure regulator.

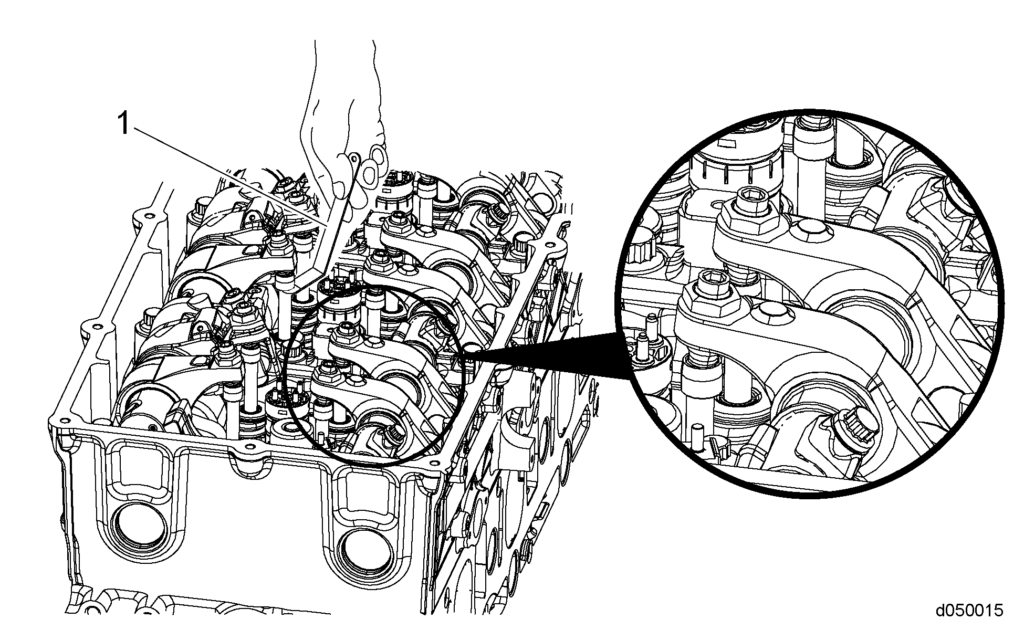

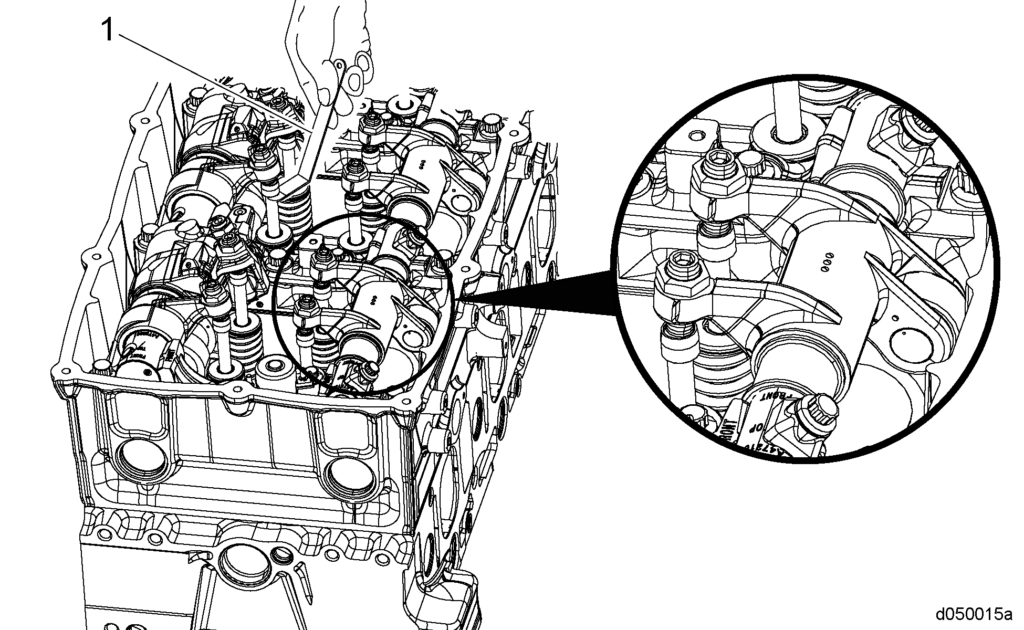

18. Prime pump with shop air. Using a rubber tipped air gun to seal around the DEF pump inlet fitting, apply clean regulated shop air to the DEF pump inlet fitting for three to five seconds.

d140723a

19. Connect all DEF lines and electrical connections. Go to step 20.

NOTE: Performing the Selective Catalytic Reduction Airless Dosing System (SCR ADS) Self-Check Routine may fail the first couple of times until the system is fully primed.

20. Perform Selective Catalytic Reduction Airless Dosing System (SCR ADS) Self-Check Routine two times to further prime the system. Ignore the results of these two tests and Go to step 21.

21. Perform Selective Catalytic Reduction Airless Dosing System (SCR ADS) Self-Check Routine to check the operation of the system. Did the SCR ADS test pass?1. Yes; replacing the DEF Pressure Relief Valve (PRV) in the kit resolved the concern. No further diagnostics or repairs are needed.

2. No; replace the DEF pump.